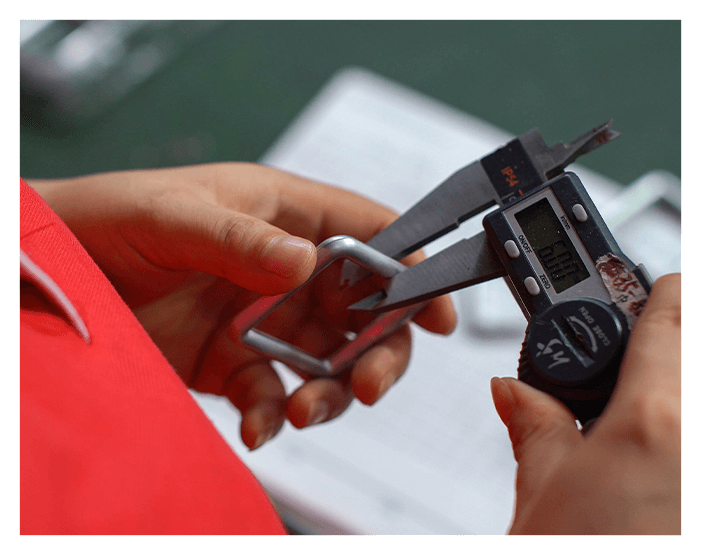

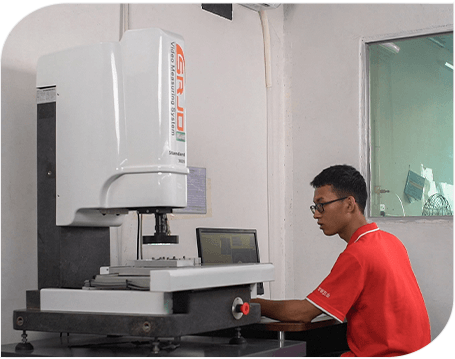

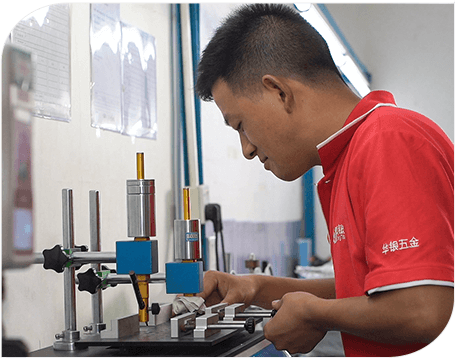

Technical assessment

Before the production stage begins, our engineering team performs a technical assessment on your parts design. This includes an assessment on important factors such as material, surface finish, structure, process, and other details of your 3D and 2D drawings.