Aluminum die casting is a high-pressure metal forming process used to create complex, near-net-shaped parts from molten aluminum alloy. The process injects aluminum alloy under extreme pressure into a custom steel mold located inside an automated machine. The aluminum die casting process provides a cost-effective, efficient way to produce durable, precision parts that meet the demanding requirements of today's high-performance, high-temperature, and corrosion-prone environments.

With 18 years of experience as an aluminum die casting manufacturer, we operate an 8,000-square-meter aluminum alloy die casting factory staffed by 200 skilled employees. Our capabilities include 10 presses ranging in size from 250 tons to 2,000 tons, enabling us to produce high-quality aluminum die casting components for both low and high-volume production programs. We specialize in high-pressure die casting and offer a comprehensive range of other die casting processes.

Beyond manufacturing, we provide one-stop solutions, including rapid prototyping, mold development, die casting, cnc machining and surface treatment, ensuring products fully meet your requirements. Our customized aluminum die casting solutions are designed to deliver precision and quality to global customers.

For detailed insights and inquiries about our precision aluminum die casting services, please don't hesitate to reach out. Contact us for further information, or call +86 13143439313 to have a conversation with one of our specialists.

Aluminum die casting stands out for its ability to efficiently produce highly complex shapes with tight tolerances that other processes like extrusion and machining struggle to achieve. This makes it ideal for manufacturing intricate components such as automotive transmissions and engine blocks. Additionally, it offers the flexibility to create parts with either textured or smooth surfaces and is capable of handling a wide range of part sizes, from very small to large components.

Our aluminum die casting standards ensure exceptional quality through the use of high-purity aluminum alloys, precise dimensional accuracy, and smooth, defect-free surfaces. Each casting is designed to meet strict mechanical property requirements, including strength, hardness, and elongation, verified through rigorous testing and quality control. The die casting process is meticulously controlled, from melt temperature to cooling rate, while comprehensive inspections using X-ray, ultrasonic, and visual techniques guarantee compliance with the highest quality standards.

| Material | Code | Tensile Strength | Thermal Conductivity | Features |

|---|---|---|---|---|

| Aluminum A380 | YL112 | 325 | 96 |

Optimum combination of mechanical, casting and thermal properties |

| Excellent fluidity, pressure resistance, thermal crack resistance, widely used in engine bases, hand tools, electronic equipment chassis, gearbox casings, household furniture, etc. | ||||

| Excellent pressure resistance and fluidity | ||||

| Aluminum A360 | yl101 | 317 | 113 | preservative |

| High temperature strength | ||||

| Excellent thermal cracking and air tightness | ||||

| Aluminum ADC12 (YZALSI12) | YL113 | 325 | 96 | improve liquidity |

| ·Good liquidity. | ||||

| Cannot be strengthened by heat treatment, low tensile strength | ||||

| Aluminum ADC10 | YL101/YL104 | 194 | 96 | good corrosion resistance |

| High impact toughness and yield strength | ||||

| Slightly poor casting performance |

Huayin Precision, as a professional aluminum alloy die casting manufacturer and aluminum die casting service provider in China, we have a production team of 200 employees, a team of experienced mold designers and mold manufacturing engineers who have been working in the industry for more than 10 years.

Huayin Die Casting is an ISO-certified company with more than 20 experienced quality engineers and advanced testing equipment to control every production link in accordance with manufacturing standards to ensure the manufacture of high-quality prototypes and aluminum die casting Components.

We provide a wide range of possible material types, surface finish options, tolerances, and manufacturing processes for your aluminum molded parts. Based on your custom needs, we can produce different shapes, sizes, and thicknesses of aluminum alloys for die casting.

30-day quality assurance, no matter when and where, quick response service within 7*24 hours, and solve problems within 1-3 working days

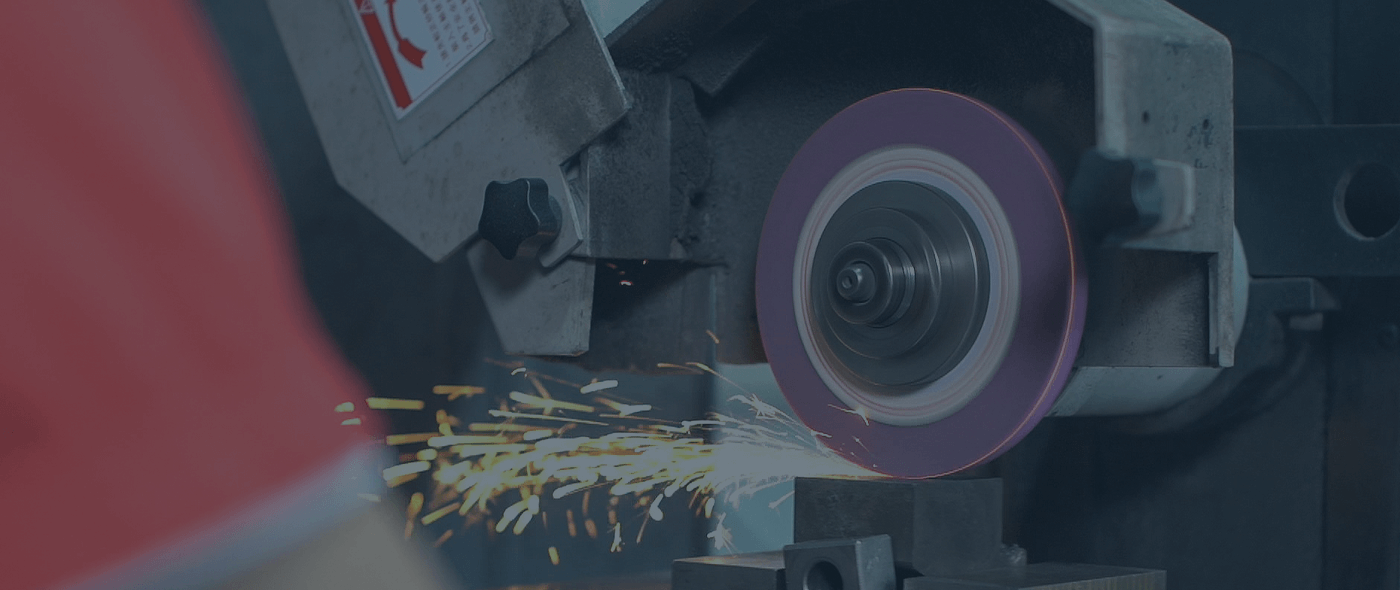

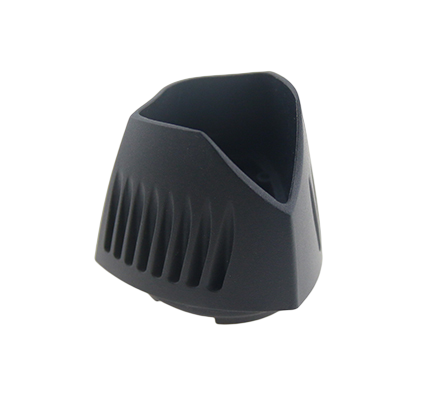

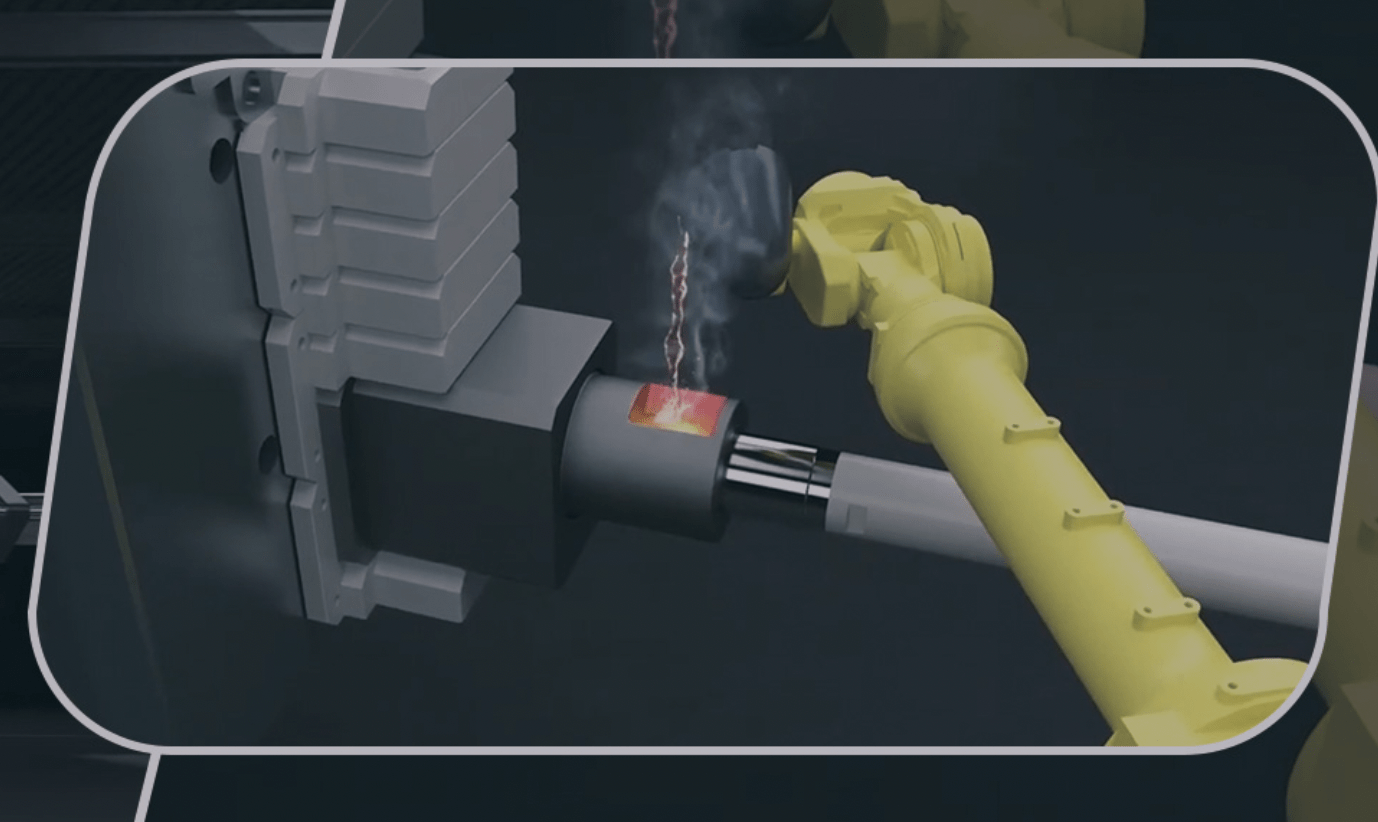

With state-of-the-art production equipment, we can produce custom aluminum die castings for you. Our die casting mold equipment, aluminum die casting machines, CNC machining centers, different surface treatment lines are shown below.

Aluminum die casting is a manufacturing process that utilizes reusable steel molds (dies) to create geometrically complex metal parts. Molten aluminum alloy, prepared in a furnace, is injected under high pressure into the dies. This rapid injection ensures the metal fills intricate details. The aluminum then rapidly cools and solidifies within the mold, taking its precise shape. The resulting parts are near-net-shaped, potentially requiring minimal post-processing steps.

Mold design

Mold making

Product die casting

Deburring

Tapping

Polishing

Surface treatment

Full inspection

Packaging

Shipment

The ultimate stage in precision die casting is post-processing and finishing, which involves applying various techniques to eliminate surface defects, enhance mechanical or chemical properties, and improve the cosmetic appearance of cast parts. We offer you a variety of high-quality finish options to match your final product. All our finishes are ROHS and REACH compliant.

Polishing

Polishing refers to the processing method that uses mechanical, chemical or electrochemical action to reduce the surface roughness of the workpiece to obtain a bright and flat surface. It is a modification and processing of the workpiece surface using polishing tools and abrasive particles or other polishing media.

Learn More>

Electroplating

Electroplating is the process of depositing metal or alloy on the surface of the workpiece by electrolysis to form a uniform, dense and well-bonded metal layer, which is called electroplating. Simple understanding is the change or combination of physical and chemical.

Learn More>

Baking paint

Baking paint is a spray paint production process. The method is to polish the die casting parts to a certain degree of roughness and spray several layers of paint on the substrate, and then bake and set at high temperature. At present, this process has higher requirements for paint and better color rendering. It is mainly divided into two categories: low-temperature baking paint and high-temperature baking paint. The temperature of low-temperature baking paint is between 140°C and 180°C, and the temperature of high-temperature baking paint is between 280°C and 400°C. Depending on the paint, whether to perform low-temperature paint or low-temperature paint is selected. High temperature paint.

Learn More>

Powder coating

The powder coating is sprayed onto the surface of the die casting with a powder spraying equipment. Under the action of static electricity, the powder will be uniformly adsorbed on the surface of the die casting to form a powder coating. After high temperature baking and leveling curing, the powder coating becomes the final coating of different types of powder coatings; the texture can be adjusted to various effects, such as smooth surface, sand texture, foaming, etc.

Learn More>

Passivation

Passivation is a process in which a metal is treated in a nitrite, nitrate, chromate or dichromate solution to form a chromate passivation film on the metal surface. It is often used as a post-treatment for zinc and cadmium coatings to improve the corrosion resistance of the coating; the protection of non-ferrous metals; and the adhesion of the paint film, etc.

Learn More>

Sandblasting

Sandblasting is to use compressed air as the power to form a high-speed jet beam, and spray abrasives (steel grit, brown corundum, glass beads, emery, etc.) at high speed to the surface of the die casting to be treated, so that the appearance of the outer surface of the die casting changes. Due to the impact and cutting effect of the sand on the surface of the die casting, the surface of the die casting can obtain a certain cleanliness and different roughness, so that the mechanical properties of the surface of the die casting can be improved, thus improving the fatigue of the die casting. It increases the adhesion between it and the coating, prolongs the durability of the coating film, and is also beneficial to the flow and decoration of the coating.

Learn More>

Anodizing

Anodizing is a surface treatment process that uses electrochemistry to form a layer of Al2O3 (aluminum oxide) film on the surface of aluminum and aluminum alloy. Through anodic oxidation, the surface state and performance of the material can be changed, thus improving corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface.

Learn More>

Cataphoresis

Cataphoresis, also called electrophoresis deposition(cationic electrophoresis), is a surface treatment that consists of electrochemically depositing an epoxy-type coating on a metal part (steel, cast iron, aluminium, magnesium, etc.)

Learn More>The precision aluminum die casting molded parts we produce are mainly involved in consumer electronics, automobiles/automotive, beauty and medical care, smart home, communications, industry and other industries. Our team will witness the whole process of each product from DFM to mass production. We hope we have the opportunity to help you

01 What is the tonnage of your aluminum alloy die casting machine?

Our aluminum alloy die casting machine has 180T/280T/320T/400T

02 How long does the mold opening cycle of aluminum alloy die casting take?

We have our own die cast mold room. Generally, the mold opening cycle of aluminum alloy die casting is about 20-25 business days.

03 Can aluminum alloy die casting be oxidized?

Yes, it is OK for aluminum alloy die casting built-in parts without appearance requirements, but oxidation treatment is not recommended for appearance parts.

04 What surface treatments can be done for aluminum alloy die casting?

Aluminum die casting parts can be electroplated, painted, dusting, electrophoresis, passivation.

05 Are aluminum alloy die-casting products strong and durable?

Aluminum die-cast products are strong, lightweight, and durable, with excellent resistance to wear and corrosion, making them ideal for demanding applications such as automotive, engine mounts and gearbox casings can handle high-intensity loads.

06 What aluminum alloys are available for die casting?

Common options include ADC12 and A380. Recommendations are made based on performance, application environment, and budget. For example, specific grades are suggested for excellent thermal conductivity or other specialized requirements.

07 How does batch size impact production pricing?

Larger batches reduce unit costs as mold expenses are distributed and production efficiency increases. In contrast, small-scale production results in higher unit prices, which decline with increased batch sizes.

Die casting is one of the most versatile and widely used manufacturing techniques, offering high precision and excellent repeatability. When it comes to choosing materials for die casting, aluminum and zinc are two of the most common options.

Die casting, a precise and efficient metal manufacturing process, is highly favored across industries for producing complex, high-volume metal parts with superior surface finishes.

Aluminum is one of the most versatile materials used across industries, prized for its lightweight nature, corrosion resistance, and thermal conductivity.