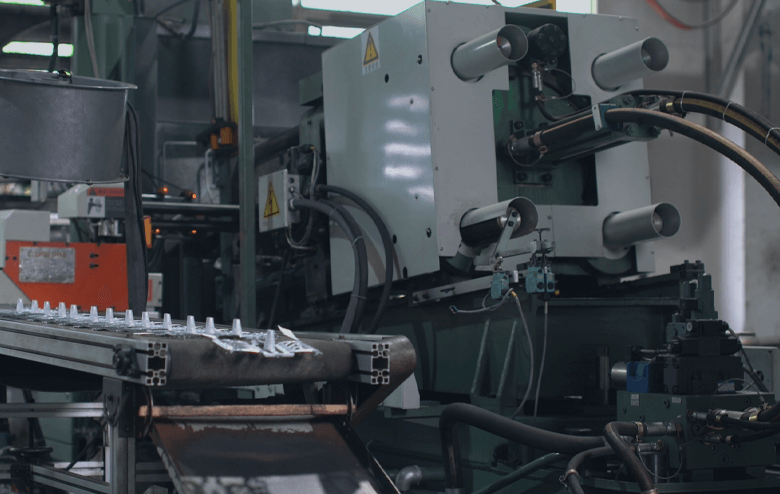

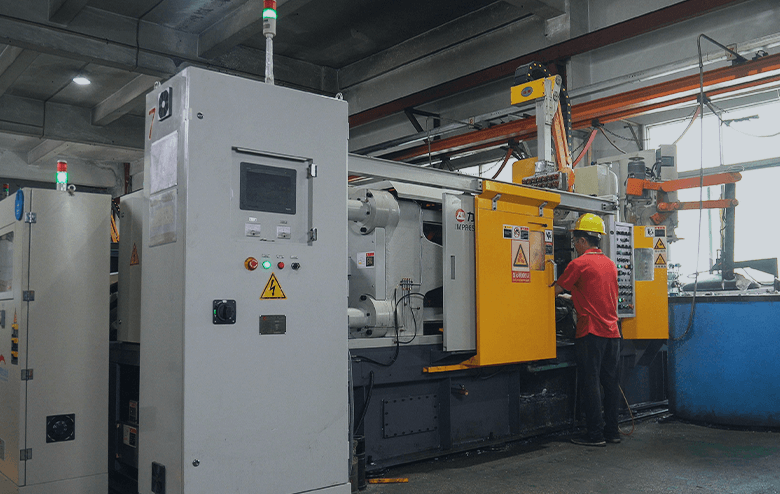

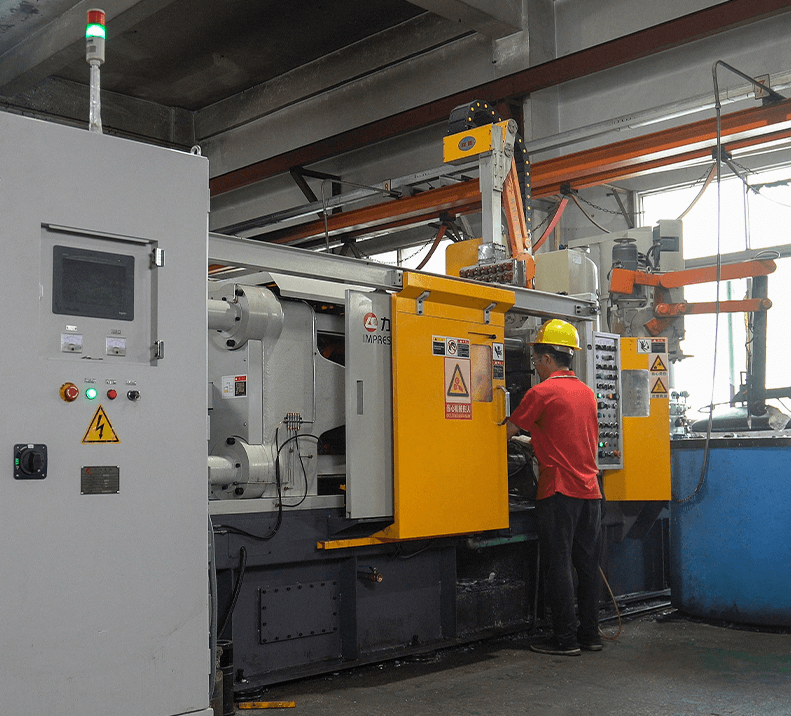

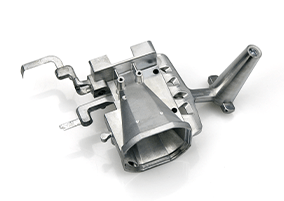

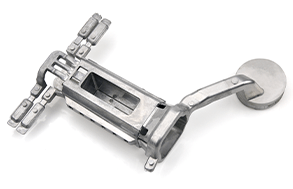

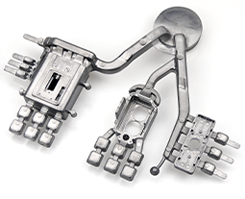

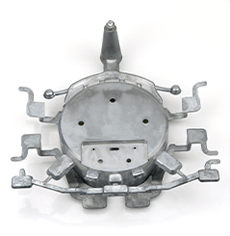

Aluminum Alloys

Aluminum die casting alloys, like A380, A360, A390, A413, ADC-12, and ADC-1, are lightweight structural metals. Comprising silicon, copper, magnesium, iron, manganese, and zinc, these alloys offer high thermal and electrical conductivity, excellent casting performance, and filling ability. Their small density and high strength ensure good mechanical properties even under varying temperatures. Learn More About Aluminum Die Casting