Zinc die casting, also known as zinc alloy die casting, is a high-pressure metal casting process that involves melting a zinc alloy (due to its ductility, impact strength, and low melting point) and injecting it into an already prepared die casting mold. Furthermore, the casting process occurs under lower heat due to the material’s low melting point. Hence the name “hot chamber die casting process.”

As an 18-year-old zinc die casting manufacturer in China, we offer zinc die casting with a variety of zinc alloy options such as ZAMAK alloys and ZA alloys. ZAMAK alloys are a popular choice for applications where good castability and cost-effectiveness are crucial and ZA alloys provide superior strength and bearing properties, ideal for projects with demanding performance requirements. Our advantage is not only to provide one-stop production from rapid prototyping, product mold opening, die casting to surface treatment, but also to provide customers with a full range of die casting parts customization solutions to create products that fully meet your needs.

Because of flexible characteristics and cost efficiency, zinc die cast components are commonly used in various industries such as plumbing, consumer electronics, automobile and beauty care products. Zinc die castings are available in applications including gears, fasteners, housings, connectors and decorative components. Our team will witness the whole process of each product from DFM to mass production. We hope to have the opportunity can help you.

| Material | Code | Features | Purpose | |

|---|---|---|---|---|

| Zinc | YX040(NO.3) |

1. Low melting point and long mold life 2. Good casting performance, can die-cast particularly complex thin-walled parts 3. Not easy to stick to the mold, with good room temperature performance 4. Good welding and electroplating performance 5. High density and poor corrosion resistance |

Dimensionally stable high precision parts | |

| YX041(NO.5) | Medium strength alloys for chrome and non-chrome parts | |||

| YX043(NO.2) | High-strength alloys for various small thin-walled parts for chrome plating | |||

| YX081(ZA-8) | High-strength alloys for hard parts | |||

Huayin Die Casting has a team of more than 20 engineers who have been in the industry for more than 10 years, and can provide you with professional technical support within 7 * 24 hours.

HYDieCasting emphasizes quality in zinc die casting processes through ISO 9001:2015 certification, internal quality control and testing, ongoing audits and improvements, and the use of high-precision inspection equipments.

We provide one-stop production customization services for rapid prototyping, mold, die casting, CNC machining, surface finishing treatment, assembly and logistics, packaging & shipping.

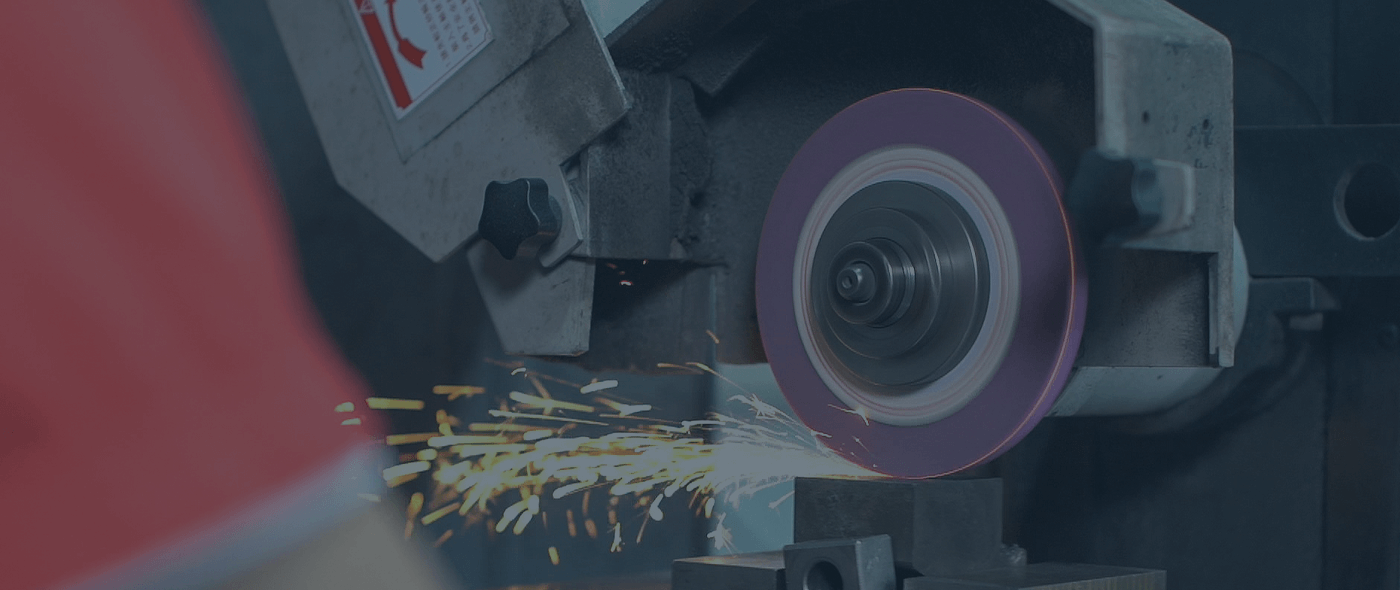

HYDieCasting has 10 Horizontal Hot Chamber Machines, capacities ranging from 88 to 800 tons, allowing for an annual zinc die casting capacity of over 12 million pounds. We are committed to expanding this capacity by continually investing in more die cast machines. Leveraging advanced die casting technology, we ensure intricate designs, exceptional dimensional accuracy, faster production times and less material waste.

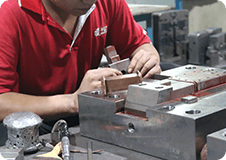

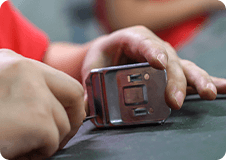

With state-of-the-art production equipment, we can produce custom zinc die castings for you. Our die casting mold equipment, zinc die casting machines, CNC machining centers, different surface treatment lines are shown below.

Mold design

Mold making

Product die casting

Deburring

Tapping

Polishing

Surface treatment

Full inspection

Packaging

Shipment

In order to provide our customers with a one-stop solution, we are able to offer you a variety of high quality surface treatment options to match your end product. All our finishes are ROHS and REACH compliant.

Polishing

Polishing refers to the processing method that uses mechanical, chemical or electrochemical action to reduce the surface roughness of the workpiece to obtain a bright and flat surface. It is a modification and processing of the workpiece surface using polishing tools and abrasive particles or other polishing media.

Learn More>

Electroplating

Electroplating is the process of depositing metal or alloy on the surface of the workpiece by electrolysis to form a uniform, dense and well-bonded metal layer, which is called electroplating. Simple understanding is the change or combination of physical and chemical.

Learn More>

Baking paint

Baking paint is a spray paint production process. The method is to polish the die casting parts to a certain degree of roughness and spray several layers of paint on the substrate, and then bake and set at high temperature. At present, this process has higher requirements for paint and better color rendering. It is mainly divided into two categories: low-temperature baking paint and high-temperature baking paint. The temperature of low-temperature baking paint is between 140°C and 180°C, and the temperature of high-temperature baking paint is between 280°C and 400°C. Depending on the paint, whether to perform low-temperature paint or low-temperature paint is selected. High temperature paint.

Learn More>

Powder coating

The powder coating is sprayed onto the surface of the die casting with a powder spraying equipment. Under the action of static electricity, the powder will be uniformly adsorbed on the surface of the die casting to form a powder coating. After high temperature baking and leveling curing, the powder coating becomes the final coating of different types of powder coatings; the texture can be adjusted to various effects, such as smooth surface, sand texture, foaming, etc.

Learn More>

Passivation

Passivation is a process in which a metal is treated in a nitrite, nitrate, chromate or dichromate solution to form a chromate passivation film on the metal surface. It is often used as a post-treatment for zinc and cadmium coatings to improve the corrosion resistance of the coating; the protection of non-ferrous metals; and the adhesion of the paint film, etc.

Learn More>

Sandblasting

Sandblasting is to use compressed air as the power to form a high-speed jet beam, and spray abrasives (steel grit, brown corundum, glass beads, emery, etc.) at high speed to the surface of the die casting to be treated, so that the appearance of the outer surface of the die casting changes. Due to the impact and cutting effect of the sand on the surface of the die casting, the surface of the die casting can obtain a certain cleanliness and different roughness, so that the mechanical properties of the surface of the die casting can be improved, thus improving the fatigue of the die casting. It increases the adhesion between it and the coating, prolongs the durability of the coating film, and is also beneficial to the flow and decoration of the coating.

Learn More>

Anodizing

Anodizing is a surface treatment process that uses electrochemistry to form a layer of Al2O3 (aluminum oxide) film on the surface of aluminum and aluminum alloy. Through anodic oxidation, the surface state and performance of the material can be changed, thus improving corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface.

Learn More>

Cataphoresis

Cataphoresis, also called electrophoresis deposition(cationic electrophoresis), is a surface treatment that consists of electrochemically depositing an epoxy-type coating on a metal part (steel, cast iron, aluminium, magnesium, etc.)

Learn More>01 What is the tonnage of your zinc alloy die casting machine?

Our zinc alloy die casting machine has 88T/180T/280T /400t.

02 How long does it take for zinc alloy die casting to open the mold?

We have our own mold room. Generally, the mold opening cycle of zinc alloy die casting is about 10-15 days.

03 Zinc alloy die castings, how big can you make?

Zinc alloy die casting customization, we can only do products within 400MM at most.

04 What surface treatments can be done for zinc alloy die casting?

Zinc alloy die casting part can be electroplated, painted, powder coating, electrophoresis, passivation.