Cold-chamber die casting is perfect for high-melting-point metals like aluminum. In this method, metal is melted in a furnace at very high temperatures and then poured into a cold chamber for injection into the die.

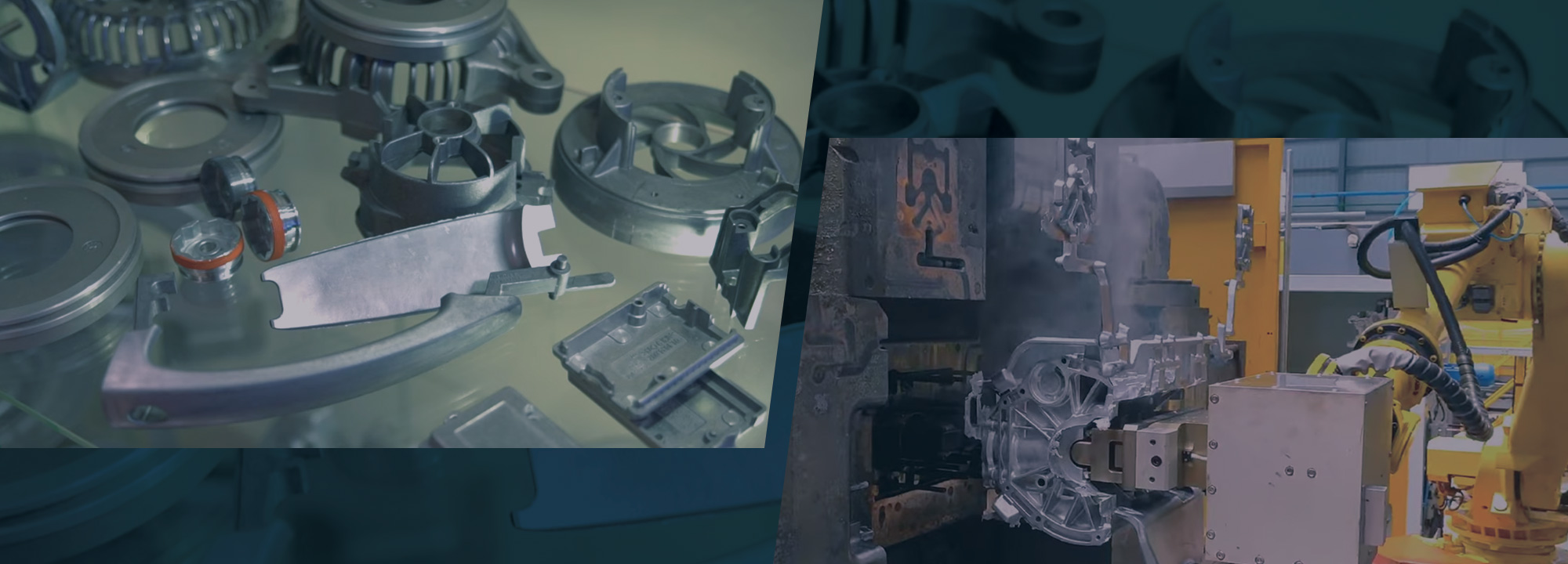

Cold chamber die casting is a high-pressure metal casting process used for alloys with higher melting points, such as aluminum, brass, and copper. In this method, the molten metal is melted in a separate furnace and then transferred to the cold chamber die casting machine. Rely on Huayin for top-notch cold chamber die casting services. Connect with us for details on our offerings or get a quote today.

The cold chamber die casting machine consists of several key components working together to produce high-quality metal parts. Here are the main components:

The process begins with the melting of the metal in external equipment furnaces. Unlike the hot chamber die casting process, where the metal is melted in the casting machine, the cold chamber process involves melting the metal in a separate furnace.

Once the metal is molten, it is transported into the cold chamber casting machine. The molten metal fills the cold chamber, which is sealed off from the rest of the machine.

A machine plunger is used to force the molten metal into the mold cavity. This process ensures that the metal completely fills the mold.

From the mold cavity, the liquid metal is transferred to shot sleeves. This transfer can be done using a machine or manually with ladles.

An injection piston is then used to force the molten metal into the die, shaping it according to the design of the component.

The metal cools and solidifies in the die cavity. Once solidified, the mold opens, and the finished casting is ejected.

Cold Chamber Die Casting offers several advantages, making it a preferred method for certain applications, especially when casting metals with higher melting points such as aluminum. Here are the key advantages of Cold Chamber Die Casting:

01 How does cold chamber die casting work?

Cold-chamber die casting is perfect for high-melting-point metals like aluminum. In this method, metal is melted in a furnace at very high temperatures and then poured into a cold chamber for injection into the die.

02 What is the application of cold die casting?

Cold chamber die casting finds extensive applications in producing high-strength components, particularly for metals with elevated melting points such as aluminum, brass, and copper. Common applications include manufacturing automotive parts, aerospace components, electronic enclosures, and various industrial products where precision, durability, and intricate details are crucial. The process is favored for its ability to efficiently produce complex shapes with tight tolerances.

03 What are the advantages of cold chamber pressure die casting?

A significant advantage of cold chamber die casting is its ability to produce denser metal castings compared to hot chamber die casting. This increased density is achieved through higher injection pressure and faster processing speed, enhancing the overall quality of the castings.

04 What are the most commonly used materials cast by using cold chamber die casting?

Cold chamber die casting is commonly employed for casting materials with elevated melting points. Aluminum alloys, copper alloys, brass alloys, magnesium alloys, and zinc alloys are among the most frequently used materials in this process.