In the dynamic landscape of die casting mold production, the material selected plays a pivotal role in determining the efficiency and quality of the process. Among the myriad choices available, aluminum emerges as a standout option for die casting molds, presenting a host of distinctive advantages. In this comprehensive exploration, we will delve deeper into each advantage, showcasing how aluminum surpasses other materials commonly used in die casting mold production.

Aluminum's remarkable strength-to-weight ratio is a key advantage that not only facilitates ease of handling but also contributes to the overall durability of die casting molds. Despite being lightweight, aluminum maintains exceptional strength, ensuring a prolonged mold lifespan and consistent performance. This unique combination not only enhances manufacturing efficiency but also significantly reduces both material and production costs.

Efficient heat dissipation is a hallmark feature of aluminum die casting molds. The material's high thermal conductivity allows for the rapid cooling of the cast metal, resulting in significantly reduced cycle times. This accelerated cooling process translates to increased productivity, making aluminum an advantageous choice for industries with high-volume production requirements.

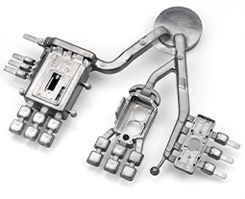

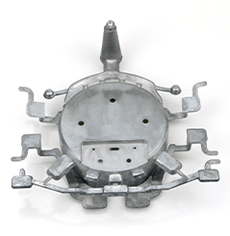

Aluminum's inherent malleability and high dimensional stability make it an ideal candidate for intricate and complex mold designs. The material can be precisely shaped to meet intricate details, ensuring a faithful reproduction in the castings. This precision not only meets but often exceeds stringent industry standards, contributing to the production of high-quality, intricate components.

One of aluminum's standout features is its inherent corrosion resistance. Particularly in environments where exposure to moisture or aggressive casting materials is a concern, this resistance enhances the mold's lifespan. By reducing the need for frequent replacements and maintenance, aluminum proves to be a cost-effective solution that adds to the overall efficiency of the die casting process.

The cost-effectiveness of aluminum die casting molds extends beyond material costs. It encompasses production efficiency and energy consumption, making it a holistic solution. Additionally, aluminum is highly recyclable, aligning with eco-friendly practices. This sustainability factor makes it a prudent choice for companies aiming to reduce their environmental footprint while maintaining cost efficiency.

In the competitive realm of die casting mold production, the advantages of aluminum are undeniable. At Huayin Precision, we not only recognize but actively harness these advantages to achieve excellence. Trust us to deliver top-tier precision and efficiency for your die casting needs. When you choose Huayin Precision, you're not just opting for a material; you're selecting a partner dedicated to innovation and perfection. Elevate your die casting experience with Huayin Precision, where every project is an embodiment of excellence, efficiency, and meticulous craftsmanship.