In the realm of precision manufacturing, aluminum CNC machining stands as a pivotal technology. But how does it influence the accuracy and functionality of components? This article delves into the key advantages of aluminum CNC machining and explores its extensive applications in modern manufacturing.

It employs precise cutting, engraving, and drilling processes to ensure aluminum parts meet high-accuracy standards across various industries. This technology is especially vital in sectors such as 3C electronics and automotive components, where precision is paramount.

Having established the significance, let us now delve deeper into its operational principles, advantages, and application areas.

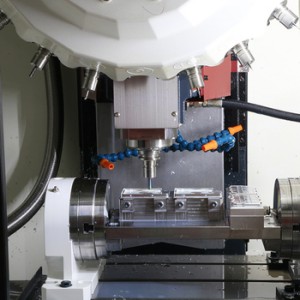

Aluminum CNC machining is a process that utilizes computer numerical control (CNC) technology to shape and fabricate aluminum materials with exceptional precision. This method is highly suitable for producing complex components that require intricate detailing and tight tolerances.

By leveraging computer-controlled machinery, it achieves high levels of accuracy and efficiency. The process involves cutting, engraving, and drilling aluminum with meticulous precision, ensuring that each part meets the exact specifications required by various industries.

The primary advantages of aluminum CNC machining include high precision, enhanced efficiency, flexibility, and superior surface treatment capabilities. These benefits make it an attractive option for manufacturers seeking to produce fine components that satisfy diverse industry demands for both accuracy and aesthetics.

Moreover, aluminum CNC machining facilitates rapid production speeds and maintains relatively low costs, making it a cost-effective solution for high-quality manufacturing. The ability to swiftly switch between different projects without significant downtime further enhances its appeal in dynamic production environments.

Aluminum CNC machining finds widespread application across numerous industries, from 3C electronics to automotive parts, catering to varying specifications and precision requirements. In the 3C electronics sector, it is instrumental in manufacturing intricate components for devices such as smartphones and laptops. Similarly, in the automotive industry, it is essential for producing high-precision parts that ensure vehicle performance and safety.

Additionally, the smart home sector relies on aluminum CNC machining for creating sophisticated and durable components that integrate seamlessly into modern living environments. Its versatility makes it a core technology for producing high-quality, complex parts essential for contemporary manufacturing needs.

Aluminum CNC machining is indispensable for manufacturing precision parts, particularly in products with stringent requirements. Its unique advantages, such as the ability to produce complex shapes with unwavering accuracy, make it irreplaceable in high-demand manufacturing scenarios.

For products that demand extreme precision and intricate designs, it offers stable and high-quality processing solutions. This reliability ensures that components perform consistently and meet the rigorous standards set by various industries, thereby enhancing overall product quality and performance.

Despite its numerous advantages, it faces challenges, especially when dealing with high-precision processing. Issues such as thermal deformation and the control of cutting forces impact the quality and accuracy of the final product.

To overcome these challenges, manufacturers implement precise temperature control measures and optimize processing paths. These strategies help mitigate thermal effects and manage cutting forces effectively, thereby enhancing both the quality and efficiency of the machining process. By addressing these potential obstacles, aluminum CNC machining maintain its high standards and continue to deliver exceptional results.

Aluminum CNC machining, with its outstanding precision and versatility, has become an essential technology in precision manufacturing. Understanding its advantages and diverse applications enables manufacturers to optimize their production processes and elevate product quality. As industries continue to demand higher accuracy and more complex components, it remains a cornerstone of modern manufacturing excellence.