You need high-quality metal components but are uncertain about which manufacturing method to select. Choosing incorrectly lead to poor precision, compromised quality, and project delays—whether dealing with aluminum die casting, sand-based shaping, or investment methods. By understanding the core elements of aluminum metal casting, including alloy choices, process options, and related techniques, you ensure your parts meet all specifications—on time and within budget.

Which involves melting suitable alloys and pouring the molten material into molds to form complex, high-precision components. Known for its lightweight properties, outstanding corrosion resistance, and excellent thermal conductivity, it is widely utilized in automotive, aerospace, and consumer appliances. Many rely on professional services and modern tooling to achieve top-tier results efficiently and cost-effectively.

Curious how this process improve part performance and trim costs? Whether you’re planning permanent mold approaches, seeking advanced equipment, or exploring DIY methods, the following sections detail key factors. You’ll learn about procedures ranging from eccentric options to plaster molding, and find tips for identifying reliable specialists who meet your specific needs.

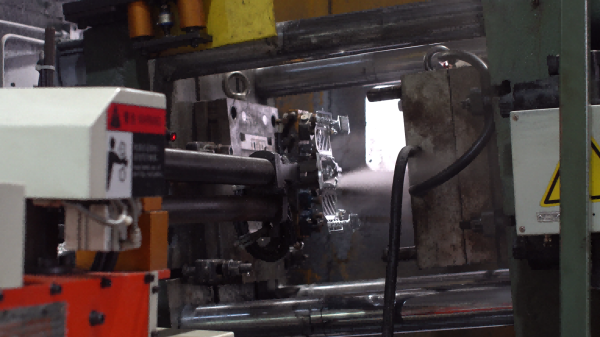

Lack of clarity on certain methods may waste resources. In aluminum metal casting, molten metal is poured into molds (sand, die, or plaster) to create intricate shapes. With careful technique selection, you tailor complexity, accuracy, and volume. Smaller runs may use basic kits, large-scale operations depend on well-managed facilities.

Sand-based molding

Mold Center Forming

Investment approaches

Material selection (castable alloys)

Mold type

Production volume & complexity

Material choice affects weight, strength, durability, and lifespan. Alloys here offer superb strength-to-weight ratios, ideal for automotive components that improve efficiency. With excellent corrosion resistance and thermal conductivity, these parts excel under harsh conditions. Whether for prototypes or large production runs, this approach ensures reliable, long-term performance.

Lightweight & Durable

Corrosion Resistant

Excellent Heat Dissipation

Automotive Components

Aerospace Structures

Electronic Housings

Defects like petrol porosity, shrinkage, or hot cracking arise if overlooked. By optimizing mold design, controlling pouring conditions, and maintaining proper temperatures, you minimize issues. Working with experienced experts ensures fine-tuning at every stage, from prototypes to finished parts, delivering consistent, high-quality outcomes.

Improved Mold & Gating Systems

Precise Temperature Control

Rigorous Quality Checks

Aluminum metal casting provides a flexible, cost-effective route to quality production. By understanding its fundamentals, selecting suitable methods, and partnering with skilled professionals, you streamline operations and enhance performance. Informed decisions lead to superior results and a stronger presence in the marketplace.

A1: Yes, It's techniques adapt well to large parts.

A2: Absolutely. Aluminum casting efficiently handle short runs.

A3: Yes, certain materials excel. With expert guidance, It still delivers reliable results.

A4: Unlike forging, It pours molten metal into molds, enabling complex shapes at lower costs.

A5: Yes, the properties of aluminum casting facilitate excellent heat dissipation.

A6: With proper design and gating, you minimize scrap and material loss.