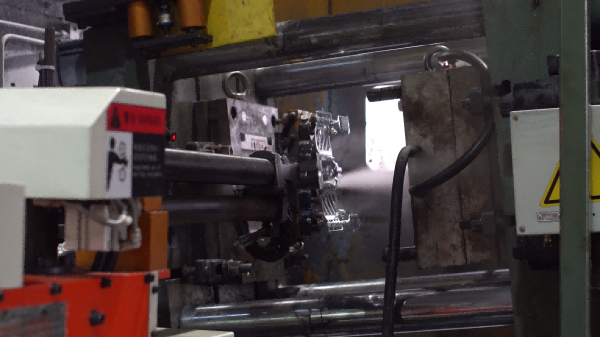

Aluminum die casting is a manufacturing process that yields, high-precision metal components, known as aluminum casting products, with exceptional dimensional stability. The selection of aluminum alloy is crucial, as it directly impacts the strength, durability, and overall performance of the final product.

Why Does the Choice of Aluminum Alloy Matter in Die Casting?

Choosing the appropriate alloy is essential because it dictates the casting efficiency, precision, and cost-effectiveness of the production process. The right alloy ensures that the products adhere to strict industry standards, reduces manufacturing costs, and customer satisfaction.

Aluminum Alloys for Die Casting: An Overview

The most commonly utilized aluminum alloys in die casting include ADC12, A380, and A360. These alloys are prized for their strength, lightweight characteristics, and corrosion resistance, making them ideal for high-precision industrial and commercial.

ADC12: Recognized for its excellent mach inability and corrosion resistance, ADC12 sees widespread use in automotive and electronic components. Its superior fluidity makes it particularly suitable for casting thin-walled and intricate parts.

A380: This alloy is the most versatile and widely used aluminum die casting alloy. A380 boasts exceptional durability and thermal conductivity, making it ideal for various industrial applications, including engine brackets, gear cases, and housings.

A360: With outstanding corrosion resistance and strength, A360 is perfect for outdoor and marine environments. It offers high pressure tightness and excellent fluidity, facilitating complex castings.

Why Are Aluminum Alloys Preferred for Die Casting?

Aluminum alloys are favored in die casting due to their unique combination of properties:

Lightweight Yet Strong: They provide a high strength-to-weight ratio, which is essential for industries such as automotive and aerospace.

Corrosion Resistance: Aluminum alloys exhibit a natural resistance to corrosion, enhancing the longevity of the aluminum casting products.

Excellent Thermal Conductivity: This characteristic makes them ideal for applications that require efficient heat dissipation, such as electronic housings and heat sinks.

Complex Design Capability: Aluminum alloys be cast into intricate shapes with tight tolerances, allowing for innovative and precise designs.

How Does Alloy Selection Affect the Die Casting Process?

The choice of aluminum alloy influences several aspects of the die casting process:

Thermal Properties: Alloys with high thermal conductivity enhance heat dissipation in components.

Strength and Durability: The alloy must satisfy the mechanical performance requirements of the aluminum casting products.

Mach inability: Alloys that are easier to machine, like ADC12, can reduce processing time and manufacturing costs.

Corrosion Resistance: Choosing an alloy with suitable corrosion resistance ensures the longevity of the component in its specific operating environment.

What Industries Use Aluminum Die Cast Components?

Aluminum die casting components are utilized across various industries due to their reliability and performance:

Automotive: Engine parts, transmission housings, and structural components benefit from aluminum's lightweight and strength.

Electronics: Enclosures, connectors, and heat sinks leverage aluminum's thermal and electrical conductivity.

Consumer Goods: Appliances, power tools, and smart home devices incorporate aluminum casting products for durability and design flexibility.

Marine and Outdoor Equipment: Components exposed to harsh environments predominantly use alloys like A360 for superior corrosion resistance.

Conclusion

Aluminum alloys such as ADC12, A380, and A360 play an essential role in die casting, offering unparalleled benefits like precision, durability, and versatility. By understanding the distinct properties of each alloy, manufacturers select the optimal material for specific applications, ensuring high-quality and reliable products across diverse industries.