Are you struggling to find the right supplier for your custom die-casting needs? The wrong choice could delay production and impact your product quality. Here's how custom casting services solve these problems.

Custom casting services are essential for creating complex and precise metal components that meet your specifications. Whether for aluminum or zinc alloys, these services provide tailored solutions that ensure high quality, efficiency, and reliability in production.

Now that we know the basics, let’s dive deeper into how custom casting services work and why they are so crucial to your manufacturing process.

When seeking specific part designs, standard casting methods often fall short. It allows precise control over dimensions, shapes, and material choices, providing a perfect fit for your needs.

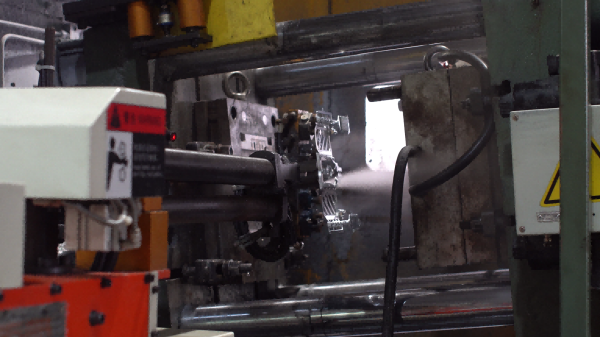

It is a manufacturing process where molten metal is poured into a mold, which solidifies to form the desired part. Unlike traditional casting, it is done based on a specific design and client requirements, providing flexibility in material selection and the final part’s geometry. This is especially crucial for industries like automotive, electronics, and consumer goods, where precision is paramount.

Standard casting methods may be convenient, but they can’t achieve the level of precision many industries need. It allows manufacturers to meet exact requirements, ensuring high-quality parts that integrate seamlessly into the final product.

It offers manufacturers the ability to create highly accurate and complex components that traditional methods might not be able to achieve. With custom casting, you have the opportunity to choose the exact alloy (such as aluminum or zinc) and design that meets your product’s requirements. This not only ensures the functionality of the part but also allows for the integration of sophisticated features that might be impossible with other methods.

Struggling with unreliable parts? Custom casting services significantly enhance product reliability, ensuring every component is designed specifically for the project, which improves long-term performance and cost efficiency.

The primary benefit of custom casting is the ability to produce parts with precise dimensions, designs, and surface finishes, all tailored to specific applications. This offers significant advantages in terms of part performance, reducing the likelihood of errors or failures. Furthermore, it optimizes production costs by eliminating the need for additional processing or modification, creating a more streamlined and cost-effective process. Additionally, manufacturers achieve a higher level of control over material properties, improving durability and functionality.

Looking for a way to refine your product designs without compromising on quality? Custom casting services offer an ideal solution, allowing for innovative designs that would be difficult or impossible with standard methods.

Product design is often a balance between creativity and manufacturability. Custom casting plays a key role here, allowing designers to push the boundaries of innovation. Unlike traditional methods, which may limit the complexity of the final product, it allows for greater flexibility in design. Whether you need complex internal structures, specific surface textures, or unique shapes, it accommodates these requirements with high precision, ensuring the final product matches your vision.

Choosing a casting service provider be overwhelming due to varying quality standards and capabilities. Understanding what to look for ensures you select a reliable partner who meets your exact needs.

Selecting the right custom casting service provider is crucial for ensuring your project’s success. It’s important to consider their expertise in the specific materials and industries relevant to your product. Ask about their previous work in similar projects and look for testimonials or case studies that highlight their experience. Make sure they have robust quality control processes in place to ensure consistency and accuracy in production. Also, check their delivery timelines and ability to meet deadlines, as late deliveries disrupt your entire manufacturing process.

Custom casting services are a key asset for businesses looking to produce high-quality, precise parts. By partnering with an experienced casting service provider, you ensure that you're manufacturing process runs smoothly, with reliable, cost-effective results.