Pain: Modern manufacturing faces numerous challenges—precision, speed, efficiency, cost-effectiveness. Traditional processes often struggle to produce lightweight, durable components without higher costs.

Agitation: As competition intensifies, firms encounter inefficiencies: material waste, extended lead times, inconsistent quality. How do producers satisfy customer demands, maintain margins, remain innovative?

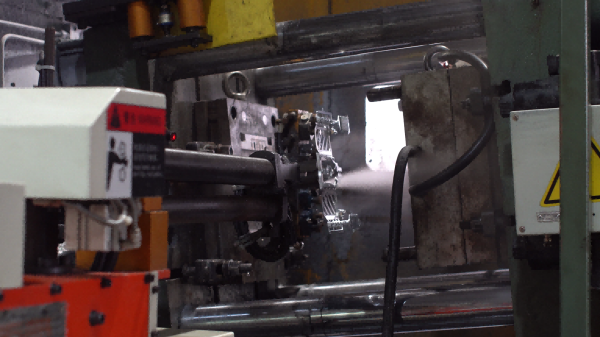

Solution: Enter aluminum casting—a technology that streamlines production, elevates quality, enables advanced, reliable, cost-effective solutions. By using step-by-step mold creation methods plus simple foundry tutorials, businesses abandon outdated techniques, evolving into modern operations.

Aluminum casting provides numerous advantages, including:

High Strength-to-Weight Ratio: Achieve robust parts without bulk using advanced alloys.

Lightweight Design: Reduce mass via permanent molds or die-based shaping, boosting performance.

Flexibility in Design: Easily form complex geometries, from molding to single-run operations.

Enhanced Efficiency: Optimize workflow with prototypes plus professional foundry methods.

As industries seek stronger, lighter, more efficient products, such alloy-based solutions excel. From automotive engineering to custom concepts, this approach—even when comparing forged against cast forms—delivers performance without sacrificing affordability. Innovative methods, from LA-based foundries to Eagle-brand processes, plus global practices like farrier module pour cooler de l’aluminum en fusion, broaden possibilities. Let’s now explore key areas where this technique shines.

Pain: Automakers must boost efficiency, performance. Heavy steel adds weight, cutting mileage, slowing acceleration.

Agitation: As standards tighten, consumers expect better experiences. Dependence on old materials hampers competitiveness.

Solution: Replacing heavier frames with lighter alloys, including die-formed engine blocks, improves fuel economy, enhances thermal management. High-pressure processes yield stronger, lighter components. This shift creates more efficient, responsive, durable vehicles.

Today’s market demands differentiation. Tailored forming strategies, including plaster-based trials or small-scale home experiments, swiftly prototype intricate shapes once too costly or complex. Integrating multiple features into single units cuts assembly steps. Evaluating die-cast vs. standard variants ensures tight tolerances, consistent quality.

Near-net-shape methods reduce excess material minimizing secondary machining. Abundant, recyclable alloys suit high-volume runs, lowering costs. Choosing reliable suppliers or specific alloy grades maintains quality at scale. Simple melting tests, even at home, verify designs before large runs.

Beyond structural needs, parts often require corrosion resistance plus aesthetic appeal. Surface modifications improve durability, hardness, aesthetics. Anodizing boosts corrosion resistance and expands color choices. Powder coatings or paints add protection, visual flair. Electroplating yields smooth, wear-resistant layers. Whether die-formed or precision-molded, finishes ensure longevity.

Conclusion

By merging strength, low mass, flexible geometry, plus cost savings, this refined metallurgical solution transforms manufacturing. From advancing automotive capabilities to enabling intricate custom concepts, it meets evolving demands. Experimentation with new alloys or basic home-foundry tests fosters robust, efficient results. As firms seek quality, efficiency, sustainability, this approach—whether via established suppliers or small workshops—ensures long-term success. Now is the time to embrace improved processes, utilize expert partners, Investing in fundamental solutions that propel products, businesses forward.