Finding the right die-casting plant in China be a daunting task, particularly when quality control and timely delivery are critical for your project's success. Whether you're seeking aluminum pressure die-casting manufacturers or looking for specific aluminum casting products, this article will guide you through the evaluation and selection of the most suitable die-casting facility to meet your needs.

When choosing a die-casting plant, pay attention to the following key factors:

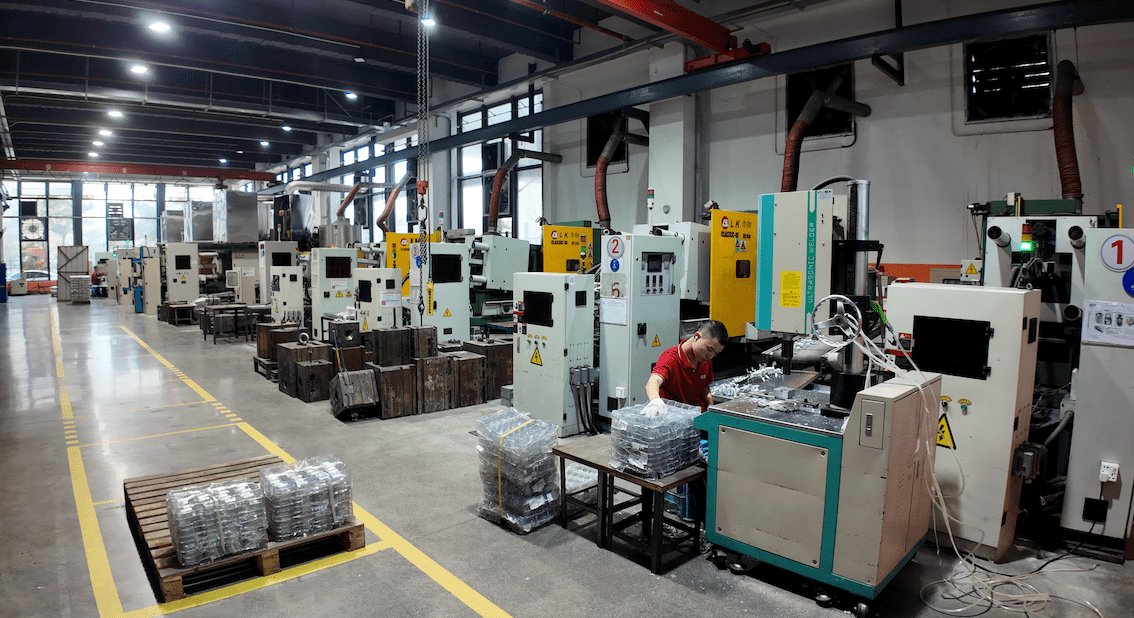

Verify that the plant possesses sufficient production capacity to meet your order requirements, whether you need small batches or large-scale production. Assess their equipment, technology, and production lines to ensure they fulfill your needs on schedule. Additionally, ensure the factory has experience with aluminum metal casting, especially if your products require specific aluminum alloys.

Seek out factories that hold ISO certifications, as these credentials reflect adherence to international quality standards. A robust quality control process guarantees product consistency and reliability, thereby reducing the defect rate. Furthermore, if your project involves high-pressure die-casting aluminum alloys, the factory must maintain strict quality control systems to ensure material integrity.

Select factories with experience in your specific industry. For instance, if you require an aluminum casting service for automotive components, partnering with a factory experienced in that sector be highly beneficial. They will better understand your product design requirements, ensuring precision and compliance. Such facilities are familiar with industry norms and standards, providing professional insights and solutions.

Inadequate quality control leads to defective products that tarnish your brand reputation. Here are some methods to verify a factory's quality control:

Conduct on-site or third-party audits to evaluate their production processes, equipment conditions, and employee qualifications. This approach gives you a comprehensive understanding of the factory's operations.

Ensure the factory possesses international certifications such as ISO. These credentials indicate compliance with globally recognized standards in quality management.

Request samples for testing to ascertain they meet your exact specifications. This proactive measure helps identify potential issues before mass production begins.

Miscommunication leads to production delays, inaccurate specifications, and project failure. To foster smooth cooperation, focus on the following aspects:

Maintain open lines of communication to promptly address any potential issues. Regular project progress reports and feedback will help both parties stay aligned.

Recognizing cultural differences enhances communication and minimizes misunderstandings. Respecting and adapting to each other's working styles fosters a strong partnership.

Delayed deliveries disrupt your supply chain and jeopardize your product launch timeline. Employ these strategies to ensure timely delivery:

Regularly monitor the factory’s production schedule and track progress against established milestones. Proactive tracking helps identify and resolve potential delays early.

Incorporate detailed delivery terms and penalty clauses for delays within your contract. This approach incentives the factory to prioritize delivery timelines and uphold contractual obligations.

Before forming a partnership, evaluate the factory’s history of on-time deliveries. Request references or case studies from previous clients to gauge their reliability and punctuality.

Knowing where to locate suitable suppliers is equally significant. Provinces such as Guangdong, Zhejiang, and Jiangsu are major industrial hubs in China, boasting robust manufacturing ecosystems. These regions host numerous die-casting facilities, including aluminum pressure die-casting manufacturers, offering a wide array of options.

By assessing production capacity, quality control, communication, and delivery timelines, you identify a reliable die-casting plant in China. Partnering with the right facility not only ensures long-term business success but also facilitates a smooth production process. Thorough research and effective communication are essential to securing the right partner for your aluminum casting products needs.

By integrating these strategies and considerations, you confidently navigate the process of finding the ideal die-casting plant that meets all your project requirements.