Are you striving to maintain quality and precision in the production of custom parts? High pressure zinc die casting offers a reliable and efficient solution for manufacturing durable components with exceptional accuracy. This process is essential for producing high-quality parts that meet stringent industry standards.

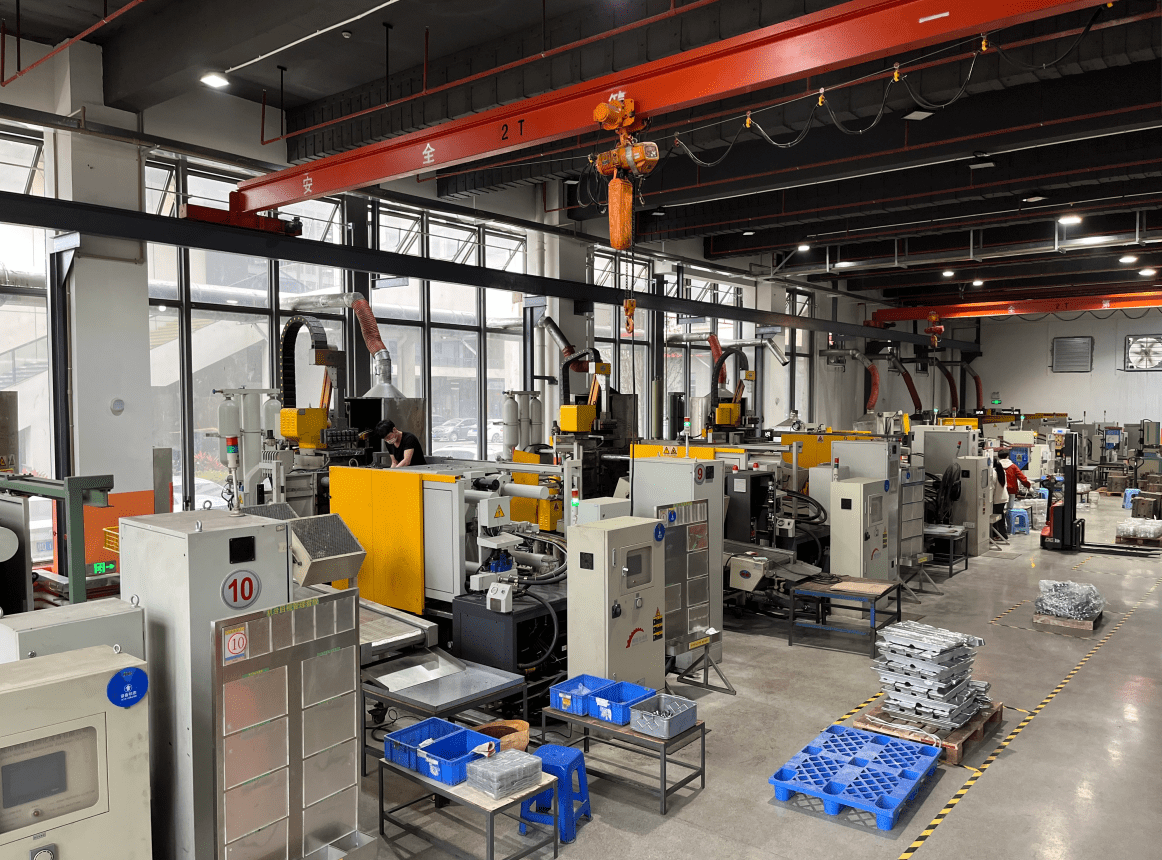

High pressure zinc die casting is a manufacturing process in which molten zinc alloy is injected into a mold at high pressure. This technique enables the production of complex and precise components and is widely utilized in industries such as automotive, consumer electronics, and smart home devices. Leading suppliers offer comprehensive services to cater to these industries' diverse needs.

By injecting molten zinc alloy into molds under high pressure, manufacturers achieve faster production cycles and enhanced accuracy. This method is particularly suited for parts that require intricate designs and superior performance, ultimately saving costs and increasing efficiency by reducing material waste and ensuring quicker turnaround times. Utilizing professional services ensures that die casting products are produced efficiently.

In this process, molten metal is forced into a steel mold, referred to as a die, under high pressure. The rapid cooling and solidification of the metal within the result in the creation of precise and durable complex parts. Use of zinc alloys, which feature a low melting point and excellent casting properties, makes this method particularly effective for high-quality production.

Engaging with experienced suppliers amplify these advantages by providing expert services tailored to your needs.

High pressure zinc die casting is employed across various industries due to its ability to produce lightweight yet strong components, including:

Selecting an experienced supplier with stringent quality control is crucial to ensuring timely delivery and high product standards. Companies like HuaYinSheng specialize in providing precision zinc die casting parts tailored to client specifications, offering custom services adhering to rigorous quality standards.

High pressure zinc die casting is an efficient and reliable manufacturing process ideal for producing complex parts across various industries. Understanding its principles and benefits empowers businesses to make informed decisions when selecting production methods, ultimately leading to enhanced product quality and cost savings. Partnering with reputable suppliers for quality die casting products is a strategic move toward achieving manufacturing excellence.